CHEMICAL DESICCANT BAGS

Discover Our Product Range : Unveiling solutions for every moisture challenge

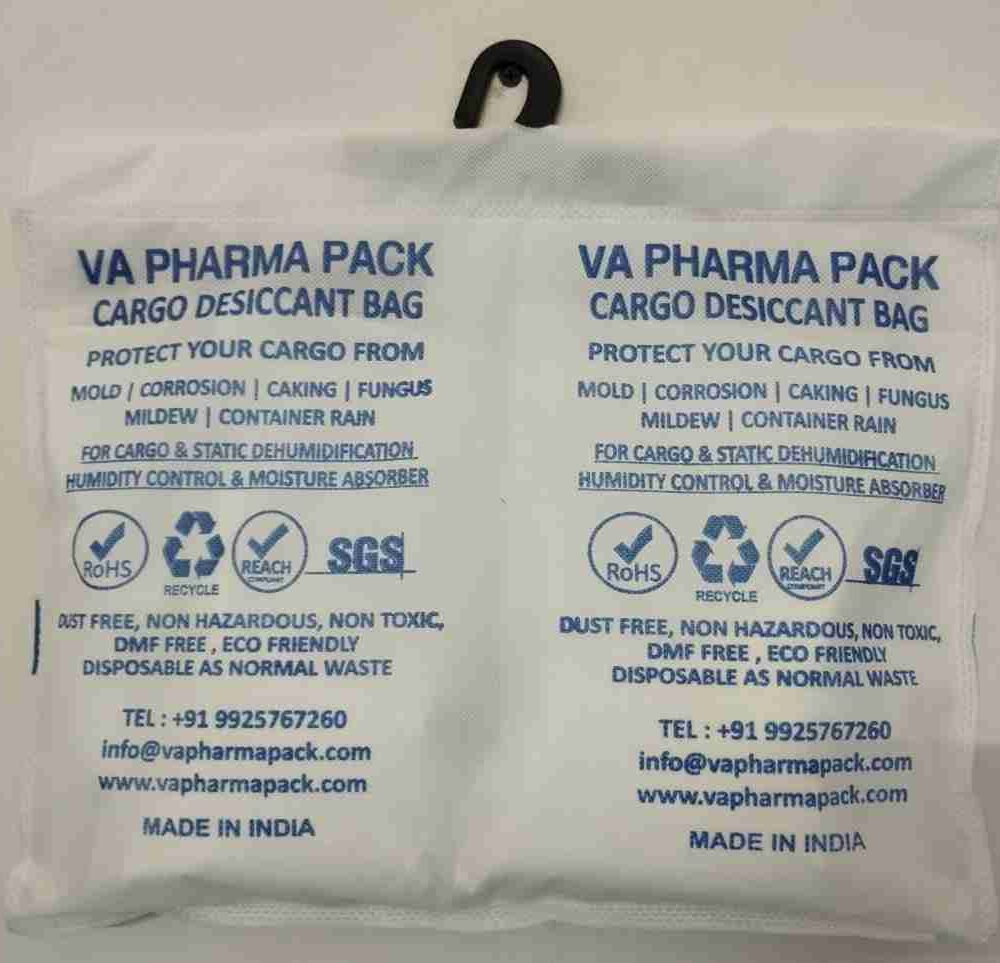

Introducing our specialized chemical desiccant bags, meticulously designed to safeguard your products from moisture damage with precision and reliability.

Crafted using advanced materials such as silica gel, activated alumina, or molecular sieves, these bags excel in absorbing moisture, ensuring optimal conditions for electronics, pharmaceuticals, food products, and more.

With customizable options to fit diverse packaging needs, our chemical desiccant bags not only preserve product integrity but also uphold stringent safety standards, making them an essential choice across industries worldwide.

Properties

- Moisture Absorption: They contain materials like silica gel, activated alumina, or molecular sieves that have high moisture-absorbing capacities.

- Regeneration: Many chemical desiccants can be regenerated by heating, making them reusable.

- Non-toxic: They are typically non-toxic and safe for use with food, pharmaceuticals, and other sensitive products.

- Indicator Capability: Some desiccant bags include moisture indicators that change color to signal when they are saturated and need replacement.

- Environmentally Friendly: Many chemical desiccants are environmentally friendly and can be disposed of safely after use. They do not contain hazardous materials and can often be recycled or repurposed.

Applications

- Electronics: Protects electronic components and devices from moisture damage during storage and shipment.

- Pharmaceuticals: Preserves the stability and efficacy of medications by preventing moisture-induced degradation.

- Food Packaging: Extends the shelf life of food products by maintaining dry conditions that inhibit mold growth and preserve freshness.

- Textiles: Prevents moisture damage to textiles during storage and transportation.

- Automotive: Protects sensitive automotive parts and equipment from corrosion caused by humidity.

- Photography: Maintains the quality of photographic films and papers by controlling humidity levels.

Quality Assurance

Equipment Support

Investing in quality and reliable equipment is what allows us to manufacture high quality sorbent products, including desiccants, oxygen absorbers, and vapor corrosion inhibitors. [1] VA Pharma Pack owns Custom Made production equipment which can produce all kinds of desiccant packets including back sealed, three-sided sealed, four-sided sealed, 2kg packaging, small cylinders, and sheets, etc. [2] We also have experienced teams to research, develop and maintain our equipment so that we are always ready to start production.

Raw materials control

We seek out the best raw materials so that our sorbent products start at the very beginning with quality. VA Pharma Pack partners with reliable and well-known raw materials suppliers, and seek to develop long-term relationships with our manufacturers. We have formed detailed classification standards for the materials we select and ensure they meet international industry standards. We develop moisture absorbing material ourselves, which can absorb up to 280% to 250% of its weight in moisture and contains no cobalt chloride and heavy metal elements.

Quality management system

VA Pharma Pack is registered with ISO and follows a strict uniform quality policy. Our transparent quality system has been highly praised among customers who have visited our factory. Our absorbent products annually earn certificates from third party certifiers such as SGS and MSDS.

Quality management system

VA Pharma Pack is registered with ISO and follows a strict uniform quality policy. Our transparent quality system has been highly praised among customers who have visited our factory. Our absorbent products annually earn certificates from third party certifiers such as SGS and MSDS.

Manufacturing Process

Material Selection and Preparation

The manufacturing process starts with selecting the appropriate desiccant material, such as silica gel, activated alumina, molecular sieves, or clay, based on its moisture-absorbing properties. The packaging material is also chosen at this stage, often using Tyvek, cotton, or non-woven fabrics, which are permeable to moisture but durable enough to contain the desiccant.

Filling

In this step, the desiccant material is measured and dispensed into the packaging material. Automated filling machines are typically used to ensure each bag contains the precise amount of desiccant, ensuring consistency across all bags. The packaging material is then prepared for sealing, often by folding or aligning the edges.

Sealing

The bags are sealed using heat sealing machines, which apply heat and pressure to create an airtight seal. This step is crucial to prevent the desiccant from spilling out and to maintain its moisture-absorbing properties. After sealing, the bags undergo a quality check to ensure there are no defects in the seal.

Packaging and Labeling

Finally, the sealed desiccant bags are grouped and packaged into larger containers for shipment. Each package or individual bag is labeled with important information, such as the type of desiccant, net weight, manufacturing date, and usage instructions. Proper labeling ensures that users can easily identify the product and understand how to use it effectively.

"VA Pharma's desiccant bags are top-notch, reducing moisture issues significantly. They offer custom sizes from small to large, fitting all our needs perfectly. Highly recommend!"

Emma Romero

"We've used VA Pharma's desiccant bags for over a year, and they're always reliable. Custom sizes from small to large ensure we get exactly what we need. Exceptional customer service too!"

Nathan Marshall

"We've used VA Pharma's desiccant bags for over a year, and they're always reliable. Custom sizes from small to large ensure we get exactly what we need. Exceptional customer service too!"

Nathan Marshall

Frequently Asked Questions

What are desiccant packs used for?

Desiccant packs are used to absorb moisture and humidity in packaging to protect sensitive products such as pharmaceuticals, electronics, and food items from degradation and spoilage.

How do desiccant packs work?

Desiccant packs work by adsorbing moisture vapor from the air inside packaging, thereby maintaining a dry environment around the enclosed product and preventing moisture-related damage.

What types of desiccant materials do you use?

We use a variety of desiccant materials including silica gel, molecular sieves, activated carbon, and clay desiccants, tailored to meet specific absorption and packaging requirements.

What packaging options are available for desiccant packs?

Our desiccant packs are available in various forms such as sachets, canisters, bags, and capsules, designed for different packaging sizes and applications to ensure effective moisture control.

How can I ensure the desiccant packs are effective?

Our desiccant packs undergo rigorous testing and quality control measures to ensure effectiveness. Follow the recommended usage guidelines based on your product’s moisture sensitivity and consult with our experts for tailored solutions.

Let's Talk!

Feel free to reach out to us with any inquiries or to discuss how our desiccant packs can meet your specific needs. We look forward to hearing from you!