Our Products

Explore Our Comprehensive Range of Productsour customizable products

01

Chemical Desiccant Bags

Introducing our specialized chemical desiccant bags, meticulously designed to safeguard your products from moisture damage with precision and reliability.

02

Agro Desiccant Bags

Presenting our specialized agro desiccant bags, tailored to protect agricultural commodities from moisture-induced damage throughout storage and transportation.

03

Glass Desiccant Bags

Introducing our innovative glass desiccant bags, engineered to provide unparalleled moisture control in scientific and industrial settings.

04

Pigment Desiccant Bags

Introducing our versatile pigment desiccant bags, crafted to preserve the quality and usability of pigments, dyes, and color-sensitive materials.

Manufacturing Process

Material Selection and Preparation

The manufacturing process starts with selecting the appropriate desiccant material, such as silica gel, activated alumina, molecular sieves, or clay, based on its moisture-absorbing properties. The packaging material is also chosen at this stage, often using Tyvek, cotton, or non-woven fabrics, which are permeable to moisture but durable enough to contain the desiccant.

Filling

In this step, the desiccant material is measured and dispensed into the packaging material. Automated filling machines are typically used to ensure each bag contains the precise amount of desiccant, ensuring consistency across all bags. The packaging material is then prepared for sealing, often by folding or aligning the edges.

Sealing

The bags are sealed using heat sealing machines, which apply heat and pressure to create an airtight seal. This step is crucial to prevent the desiccant from spilling out and to maintain its moisture-absorbing properties. After sealing, the bags undergo a quality check to ensure there are no defects in the seal.

Packaging and Labeling

Finally, the sealed desiccant bags are grouped and packaged into larger containers for shipment. Each package or individual bag is labeled with important information, such as the type of desiccant, net weight, manufacturing date, and usage instructions. Proper labeling ensures that users can easily identify the product and understand how to use it effectively.

Manufacturing Facilities

At VA Pharma Pack, our state-of-the-art manufacturing facilities are designed with precision and efficiency to deliver the highest quality desiccant bags. Our commitment to excellence is evident in every step of our manufacturing process, from the initial design to the final product.

Advanced Manufacturing Design

Our manufacturing design integrates cutting-edge technology and innovative methodologies to ensure optimal performance and reliability of our desiccant bags.

World-Class Facilities

VA Pharma Pack's manufacturing facilities are equipped with the latest advancements in production technology, ensuring we maintain our reputation for quality and efficiency.

Quality Assurance

Quality is at the heart of our manufacturing process. We adhere to strict quality control protocols at every stage of production.

Success Stories

1991

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Mauris tempus nisl vitae magna pulvinar laoreet.

2000

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Mauris tempus nisl vitae magna pulvinar laoreet.

2006

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Mauris tempus nisl vitae magna pulvinar laoreet.

What Our Happy Clients Say?

"VA Pharma's desiccant bags are top-notch, reducing moisture issues significantly. They offer custom sizes from small to large, fitting all our needs perfectly. Highly recommend!"

Emma Romero

"We've used VA Pharma's desiccant bags for over a year, and they're always reliable. Custom sizes from small to large ensure we get exactly what we need. Exceptional customer service too!"

Nathan Marshall

"We've used VA Pharma's desiccant bags for over a year, and they're always reliable. Custom sizes from small to large ensure we get exactly what we need. Exceptional customer service too!"

Nathan Marshall

Frequently Asked Questions

What are desiccant packs used for?

Desiccant packs are used to absorb moisture and humidity in packaging to protect sensitive products such as pharmaceuticals, electronics, and food items from degradation and spoilage.

How do desiccant packs work?

Desiccant packs work by adsorbing moisture vapor from the air inside packaging, thereby maintaining a dry environment around the enclosed product and preventing moisture-related damage.

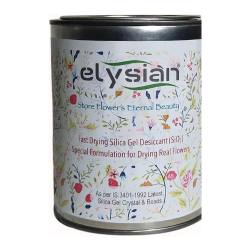

What types of desiccant materials do you use?

We use a variety of desiccant materials including silica gel, molecular sieves, activated carbon, and clay desiccants, tailored to meet specific absorption and packaging requirements.

What packaging options are available for desiccant packs?

Our desiccant packs are available in various forms such as sachets, canisters, bags, and capsules, designed for different packaging sizes and applications to ensure effective moisture control.

How can I ensure the desiccant packs are effective?

Our desiccant packs undergo rigorous testing and quality control measures to ensure effectiveness. Follow the recommended usage guidelines based on your product’s moisture sensitivity and consult with our experts for tailored solutions.

Let's Talk!

Feel free to reach out to us with any inquiries or to discuss how our desiccant packs can meet your specific needs. We look forward to hearing from you!